Abstract

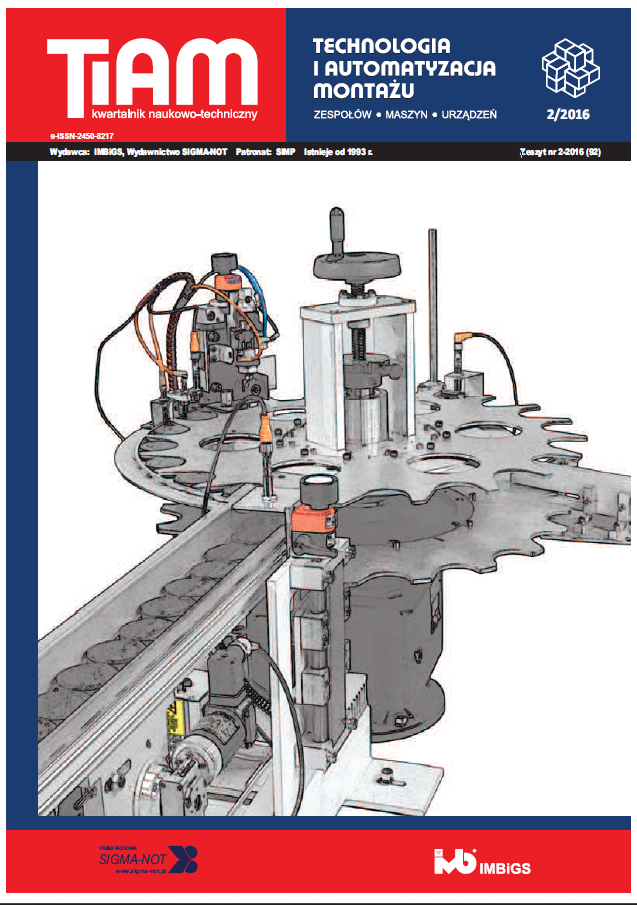

The article presents a inspection method for automatic control of internal combustion engines seals. The proposed non-contact method of inspection technique utilize 2D laser triangulation technique. In the systems based on this technique line created by the laser radiation is projected on the surface of the object. The reflected light surface is then recorded by the photosensitive array placed at an angle with respect to the direction of the laser light. Changing the distance of the test surface relative to the measuring head causes a change in the position of points on the light-sensitive sensor. For the purposes of research the experimental station was developed. During the inspection the inspected seals are placed in the socket on the rotary table. The 2D laser measuring head is mounted over the inspection zone. During the rotation of the table the current position of the seal is send to the control unit. On this basis, the measurement system controller accumulates the individual 2D profiles of inspected seal in the memory. After collecting a fixed amount of 2D profiles followed by analysis of the scanned surface of the product the inspection decision is reported. As part of the experimental studies typical seals defects were identified. Additionally in the article an example of the results of the scan surface of the seals with variety types of defects are presented. The advantages and limitations of the proposed method are discussed.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License CC BY 4.0 (https://creativecommons.org/licenses/by/4.0/)

References

Biblioteka do przetwarzania i analizy chmury punktów pomiarowych PCL, http://pointclouds.org.

Bradshaw G. 1999. “Non – contact surface geometry measurement techniques”. Dublin: Image Synthesis Group, Trinity College.

Carrara M. 1992. “Seal withdrawal and testing device”. Patent US 5167141 A.

Czajka P. i in.. 2014. „Profilometr laserowy do odtwarzania geometrii powierzchni”. Przegląd Elektrotechniczny (8): 152–156.

Garbacz P., T. Giesko. 2011. “Integrated vision systems versus custom solutions for quality inspection in industry.” Wrocław: Materiały konferencyjne Inżynieria Produkcji, s. 213–217.

Karta katalogowa produktu: Profilometr laserowy 3D-R, ITeE-PIB, Radom, http://www.itee.radom.pl.

Kowal J., A. Sioma. 2012. “Surface defects detection using a 3D vision system”. 13 International Carpathian Control Conference (ICCC), 382–387.

Laser World of Photonics: White Paper Image Processing in the Automotive Industry, http://www. world-of-photonics.com.

LJ-V/CV-X200 Series Inline 3D Inspection Image Processing System, Keyence Corporation, 2014.

Materiały informacyjne firmy SKF: Zasady doboru i stosowania uszczelnień, http://www.skf.com/pl.

Sioma A., G. Struzikiewicz. 2010. „Bezdotykowy pomiar przedmiotu obrabianego”. wiat obrabiarek (10–12): 20–24.

Tornslev K. 2005. “3D scanning using multibeam laser”. Lyngby: Technical University of Denmark.

Ultra-High Speed In-line Profilometer, LJ-V7000 Series, User’s Manual, Keyence Corporation, 2014.

Wójcicki T., P. Czajka, T. Giesko. 2010. „Automatyczna inspekcja montażu uszczelek łożysk tocznych z wykorzystaniem komputerowych metod przetwarzania i analizy obrazów”. Technologia i Automatyzacja Montażu (3): 26–31.