Abstract

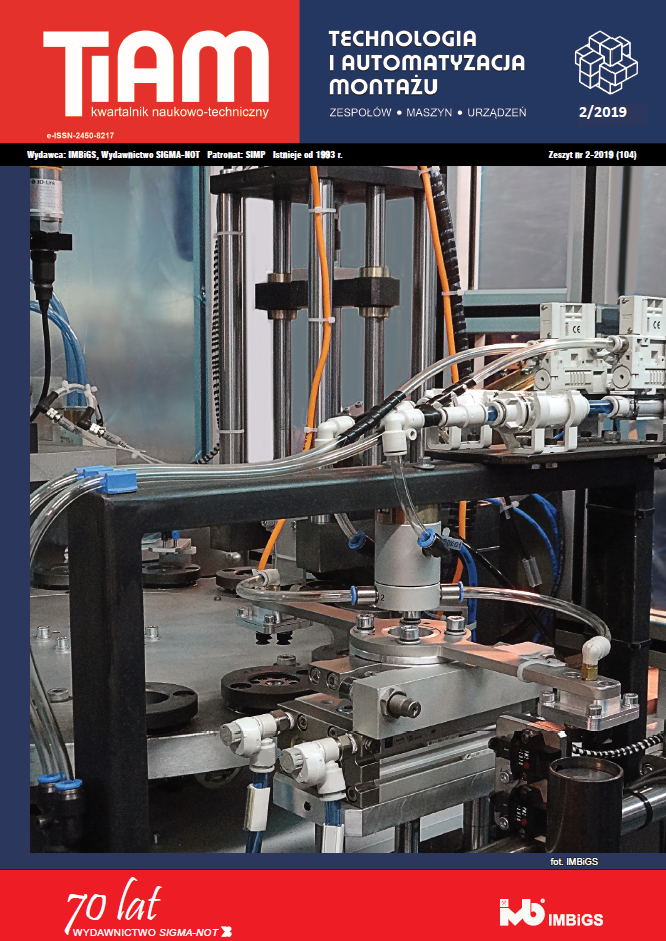

The prototype of a dispensing head of thermoplastic elastomers was designed and construct-ed at the Institute for Sustainable Technologies for a purpose-built manufacturing line for producing textile-elastomer composite glues. The elastomer dispensing head enables the transfer of the elastomer onto the moving material; it evens out the applied layer or creates discontinuous layers which are permeable for water vapour or air. The device heats the me-dium being dispensed using an oil heated conduit or electric heating elements with tempera-ture control.

This design is capable of changing the flow direction of the substrate in the manufacturing line, regulating a precise layer thickness, automatically executing setup and maintenance, and safe handling.

Using the dispensing head constructed as part of project developing the manufacturing, the BOCHEMIA company has developed innovative solutions for manufacturing technologies of multifunctional composites of innovative materials which exhibit the following properties: energy absorbing (which provided impact absorption properties), fungicidal, and bactericid-al.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License CC BY 4.0 (https://creativecommons.org/licenses/by/4.0/)

References

Fejdyś M., M. Łandwijt.2010. „Włókna techniczne wzmacniające materiały kompo-zytowe”. Techniczne Wyroby Włókiennicze 1/2:12–22.

Janicka J., R. Koźmińska.2009. „Tekstylia w materiałach kompozytowych”. Tech-niczne Wyroby Włókiennicze1: 20–28.

Kharchenko Ye. F., I. A. Kurmashova, Ye. A. Solovyova.2009. “Development and Study of Laminated Aluminum-Ceramic Armor Materials”. Techniczne Wyroby Włókiennicze 2/3: 40–41.

Kovacević S., J. Domjanić, S. Pacavar.2017. „Effects of Layer Thickness and Ther-mal Bonding on Car Seat Cover Development”. FIBRES & TEXTILES in Eastern Europe 25, 2(122): 76–82.

Perepelkin K. E. 2005. “Polymer fibre composites, basic types, principles of manufac-ture, and properties. Part 2. Fabrication and properties of polymer composite materials”. Fibre Chemistry 37(5)..

Samborski T., A. Zbrowski.2013. “Mechatronic system for the production of highly secured documents”. Solid State Phenomena. Mechatronic Systems and Materials IV 198: 27–32.

Zbrowski A., T. Samborski.2012. „Prototypowa linia do elastycznego montażu doku-mentów z zabezpieczeniem elektronicznym”. Technologia i Automatyzacja Montażu 4: 30–36.